PERLITE AS INSULATION: SUNPERL PERLITE USED AS WALL PLASTER

Nowadays with the high and ever rising cost of electricity, one must always seek alternatives to lower our day-to-day living costs. This includes the costs of the homes that we live in.

Thermal insulation of commercial and residential buildings is of paramount importance. In fact, the Government has passed law SANS 204 which now state that buildings need to be insulated to save electricity.

So – how can you save on your electricity bill by insulating your home that is not going to cost you a fortune? Look no further than SunPerl perlite wall plaster!

WHY USE PERLITE?

Perlite is a non-toxic, naturally occurring siliceous volcanic rock. Perlite is formed by the rapid cooling of viscous magma or lava. The distinguishing feature which sets perlite apart from other volcanic glasses is that when heated to a suitable point in its softening range, it expands from four (4) to approximately twenty (20) times its original volume!

Perlite is a versatile and sustainable mineral that is mined and processed with a negligible impact on the environment. The green community recognizes perlite enhanced products – like insulation – as a high-performance solution drawn from natural material of nearly unlimited supply through the world.

Sun silicates imports perlite from Turkey – which ensures that we deliver quality products to our clients!

Because of the perlite mineral’s low density and relatively low price, many commercial applications have developed over the past few years. In the construction and manufacturing fields, it is used in lightweight plasters, concrete, insulation and ceiling tiles. In horticulture, perlite can be used as a soil amendment or alone as a medium for hydroponics or for starting cuttings. When used as an amendment it has high permeability / low water retention and helps prevent soil compaction.

Perlite insulation is an organic product that does not support combustion, or rot, nor does it provide a habitat for rodents. It is ideal for use under concrete slabs, chimneys and in high-temperature applications such as pizza ovens. Perlite yields superior thermal performance.

A mere 15mm SunPerl Thermal plaster will give you the same thermal properties of a 9 inch brick wall (double brick wall) which means you will have drastically less heat loss in the winter and less heat in the summer penetrating through your building’s walls in the summer. SunPerl Thermal plaster is also very light (low density) which means it is easy to work with. It results in a lighter plaster than ordinary plaster that contains sand. This allows an artisan to apply it with ease and a lot faster.

Applying SunPerl Thermal plaster doesn’t require any special tools or specialists to do the job! All you need is your everyday plaster tools, and the time to make significant savings to your living costs!

HOW TO APPLY SUNPERL CONSTUCTION GRADE WALL PLASTER: THE STEP-BY-STEP GUIDE

Below you will find step-by-step instructions on how to apply SunPerl wall plaster to your wall. Remember that all mixing ratios are volume based.

- Step-1: Surface Preparation

- Step-2: Mixing SunPerl and Cement

- Step-3: Add water to this mixture

- Step-4: Appling SunPerl plaster

Raw materials required (Figure 1):

- SunPerl perlite (Construction grade) (± 100 Litres or 10 kg per bag)

- Cement: 42.5 MPa is recommended (± 33 Litres or 50 kg per bag)

Figure 1

Figure 1 – SunPerl and cement are the raw materials required.

Step 1: Surface Preparation

It is recommended to dampen the wall surface prior to plastering in order to prevent premature drying which results in cracking of the plaster.

Step 2: Mixing SunPerl and Cement

For internal or external plaster either one of the following mix ratios (volume) can be used:

- 3 : 1 – 1 Bag SunPerl to 1 Bag Cement; 28 – 37 Litres of water

- 5 : 1 – 3 Bags SunPerl to 2 Bags Cement; 74 – 93 Litres of water

A 3 to 1 ratio will result in a much stronger plaster, but at a cost of yield and insulation properties. Always add the minimum amount of water and then top up until the desired consistency and slump is achieved.

Figure 2

Figure 2 – Empty the bag of SunPerl construction grade perlite onto the mixing surface.

Figure 3

Figure 3 – Spread the cement over the SunPerl perlite.

Figure 4

Figure 4 – Thoroughly mix the cement with the SunPerl perlite. It is important that SunPerl perlite and cement are mixed in a dry state before adding water.

Adequate mixing is achieved once the colour of the mixture becomes uniformly light grey (almost the colour of cement).

Step 3: Add water to this mixture

Figure 5

Figure 5 – Add water in increments to the mixture whilst mixing.

Always use the minimum amount of water as shown in the mix ratio guideline then top up until desired consistency is achieved.

Figure 6

Figure 6 – Compared to ordinary concrete the mix may appear dry.

Step 4: Appling SunPerl plaster

Figure 7

Figure 7 – Check the consistency of the cement/perlite mixture.

If the consistency is incorrect, add more water to the mixture.

Figure 8

Figure 8 – Apply the cement/perlite mixture (now called plaster), to the wall with a float trowel.

The plaster is smeared with force onto the surface using an upward motion.

Figure 9

Figure 9 – Allow plaster to dry for at least one hour before applying a straight edge (called cutting).

Use the “Thumb” check to see if plaster can be cut. Attempt to indent the plaster with your thumb, if you can only make a small dent the plaster is ready for cutting.

Figure 10

Figure 10 – Use a Straight edge and Spirit level for cutting.

Figure 11

Figure 11 – Float with the surface using a steel or wooden trowel.

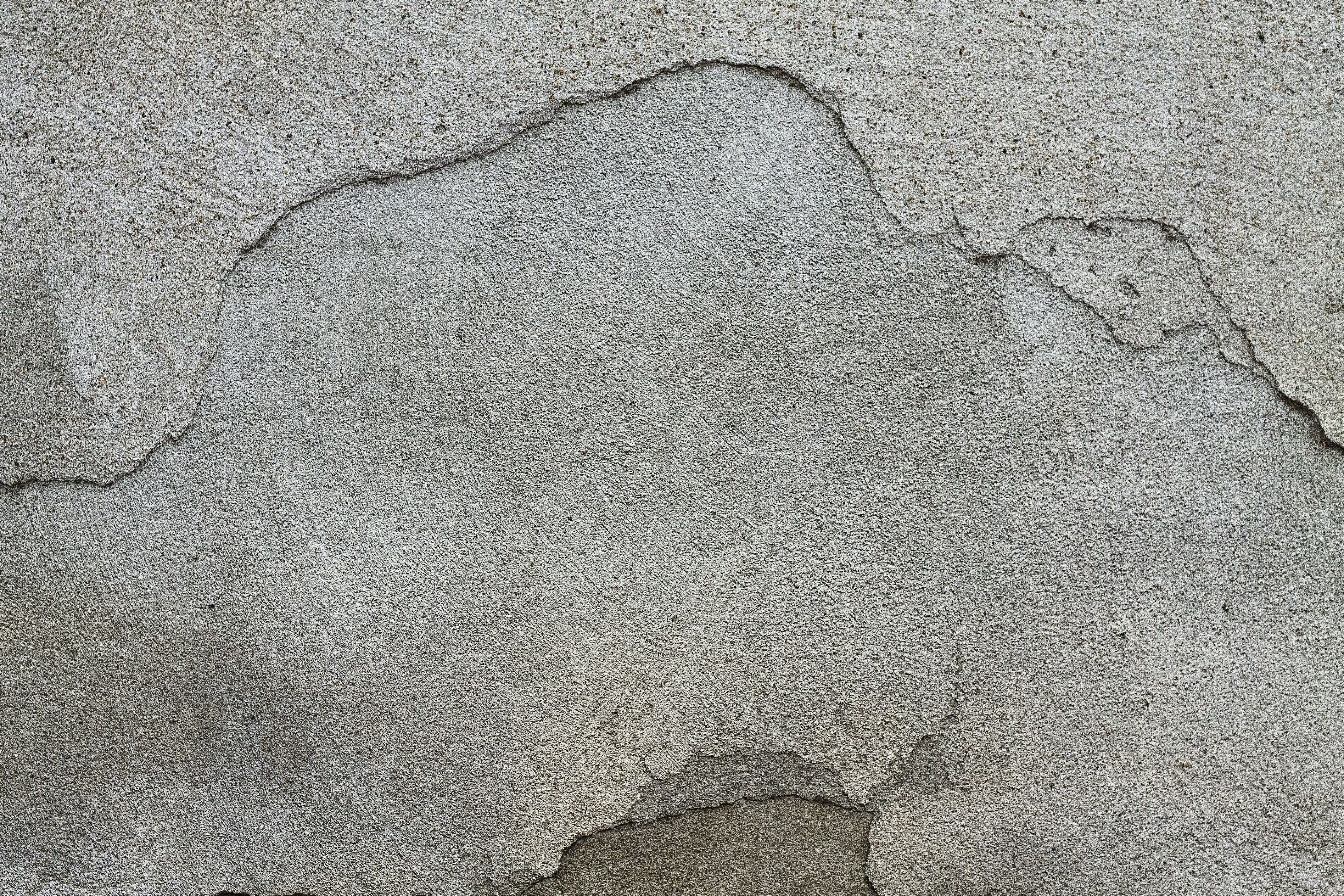

Figure 12

Figure 12 – The end result is an extremely smooth surface finish.

To prevent brittle plaster or cracks the plaster must be kept moist of at least 3 days and not allowed to dry in direct sunlight or wind.

For more information, please visit our website www.sunsilicates.co.za

No Comments